Our Infrastructure

Precision. Capacity. Commitment to Excellence.

Overview

At PI Engineering Services, our infrastructure is the backbone of everything we deliver. Designed to meet the highest industry standards, our manufacturing facility is equipped to handle high-volume production while ensuring unmatched quality, efficiency, and customization.

We have steadily invested in the latest technology, advanced fabrication lines, and highly skilled manpower to support diverse project demands — from architectural fabrication to precision assemblies and coatings.

Key Capabilities

End-to-End Fabrication

Aluminium, GI, and metal component production for shutters, ceilings, drywall systems, and more.

Assembly & Integration

In-house facility for shutter kits, ceiling panels, cladding systems, and structural hardware.

Custom Manufacturing

Scalable setup to support standard and made-to-order projects with flexibility and speed.

Surface Finishing Setup

State-of-the-art PU Coating, Powder Coating & Anodizing setups ensure corrosion resistance and aesthetic finish.

Design-to-Delivery Workflow

All manufacturing is backed by in-house engineering expertise, quality control, and client-driven timelines.

Equipment Overview

Roll Forming Machines – 4 Units

- Capacity: Up to 400 mm width | 2 mm thickness

- Ideal for shaping long strips of metal into uniform cross-sections for structural and architectural profiles.

Metal Folding Machine

- Specifications: 2400 mm fold length | Up to 1.5 mm thickness

- Enables clean, accurate bends in sheet metal for complex fabrications.

Powder Coating Unit

- Oven Size: 12’ x 5’ x 5’

- Ensures a durable, corrosion-resistant finish on both indoor and outdoor metal products.

Anodizing Unit

- Tank Size: 6’ x 2’ x 2’

- Adds a protective oxide layer to aluminium parts for enhanced appearance and corrosion resistance.

PU (Polyurethane) Painting Unit

- Job Size Capacity: 6’ x 2’ x 2’

- Provides a smooth, glossy finish with strong chemical and abrasion resistance, ideal for premium and industrial finishes.

Shearing Machine – 1 Unit

- Delivers fast, precise straight-line cuts in metal sheets with minimal wastage.

Drill Machines – 4 Units

- Facilitates precise drilling in metals and alloys for accurate hole placement.

Tapping Machines – 2 Units

- Ensures consistent internal threading of drilled holes, crucial for component assembly.

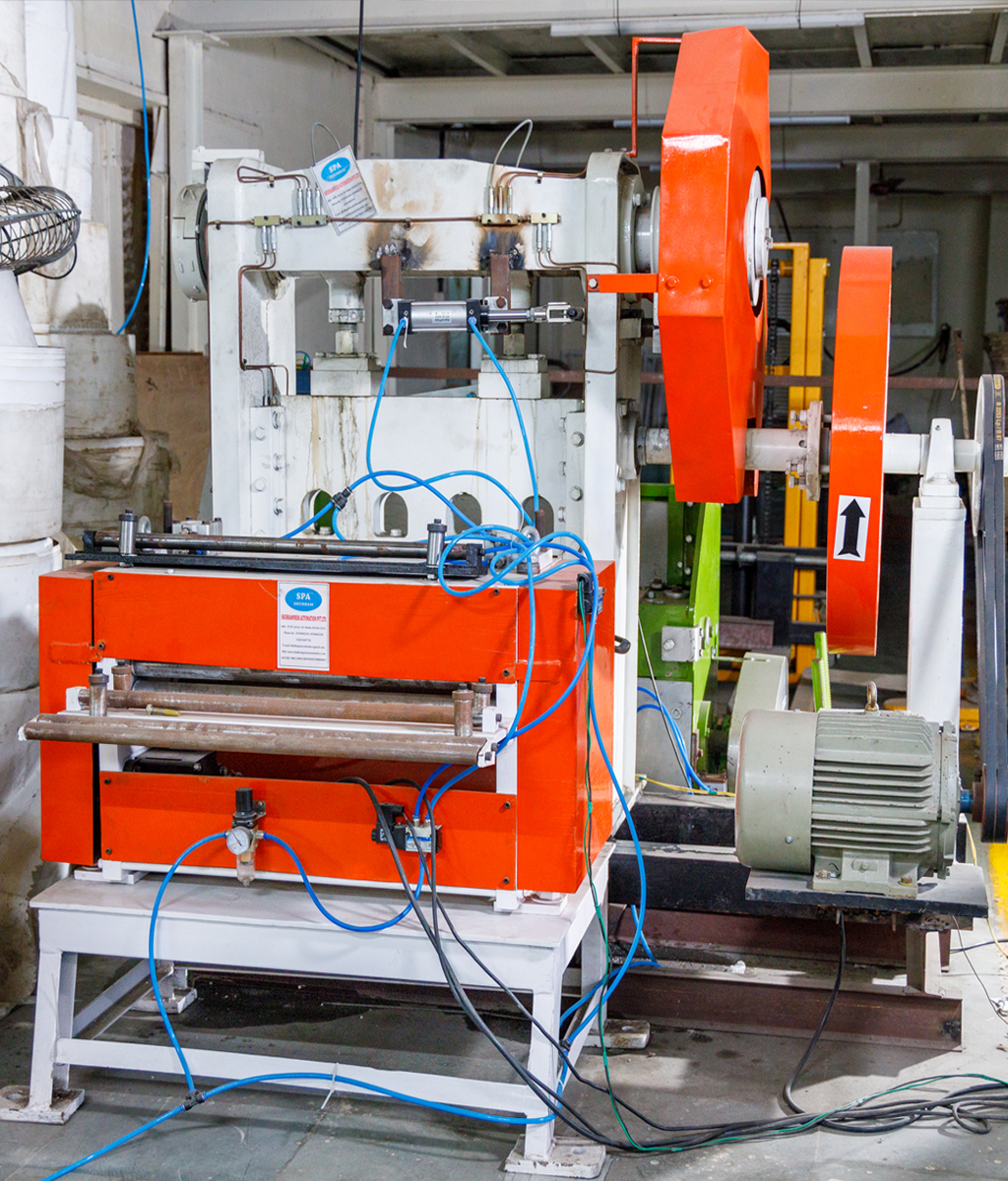

Press Machines – 4 Units

- Used for punching and shaping metal parts, supporting both mass and custom fabrication tasks.

Aluminium & Metal Cutting Machines – 4 Units

- Offers burr-free cutting of various metal profiles, enabling high-precision output.

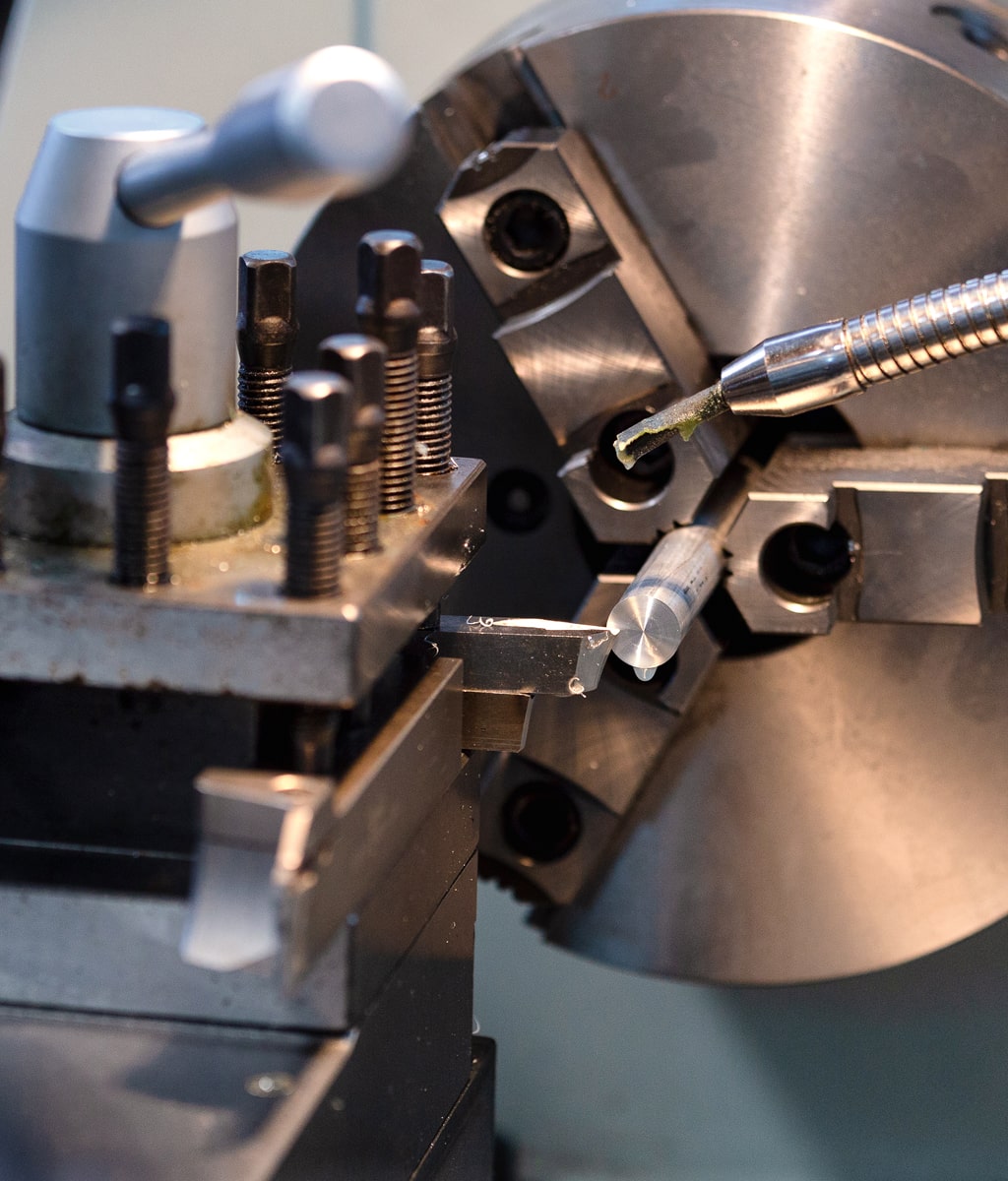

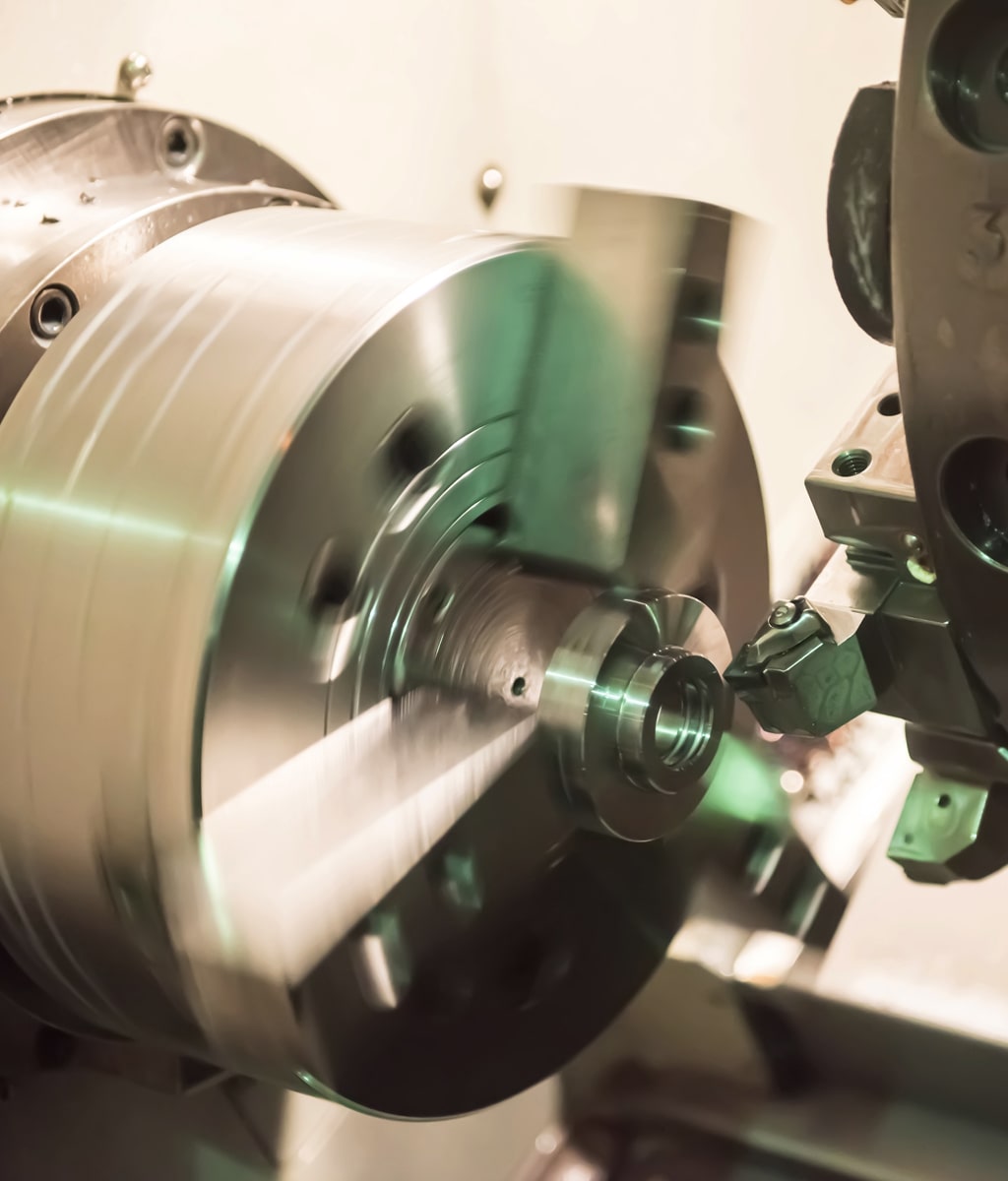

Lathe Machine (Tool Room Use) – 1 Unit

- Vital for component shaping, turning, and facing tasks, especially in custom jobs and maintenance.

Hydraulic Press – 2 Unit

- Two Hydraulic Press units (120-ton and 75-ton) equipped with die cushions for precise and efficient forming operations.

Panel Saw – 1 Unit

- Capable of cutting 8’x4’ panels with high precision and smooth operation.

Ceiling Tiles Processing Line - 1 Unit

- For producing 2’x2’ ceiling tiles with precision and uniform finish.

Cold Press For Panel Pressing – 1 Unit

- Used for uniform bonding and lamination of panels under controlled pressure.

Discover how our smart, sustainable, and scalable metal engineering solutions can add value to your business.